According to Allied Market Research, the market for robotic material handling is expected to grow to nearly $39 billion by 2022. This shows an increased demand for this robotic solution, with more manufacturing industries automating the process.

The reasons for this drastic growth differ from industry to industry, but the most common one is competitive advantage. In many sectors, robotic automation has unlocked their production potential, enabling industries to dominate in the market.

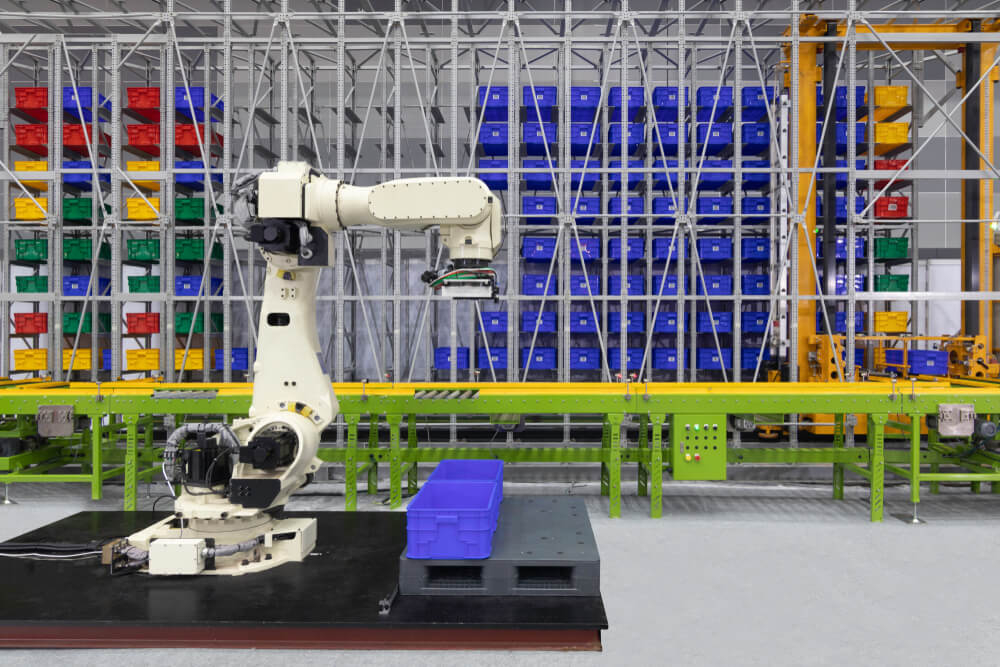

That’s just part of the reason why you should think of investing in palletizing robot for your industry. Below we look deeper into how automating your material handling is good for business.

-

Increased Productivity

One of the biggest benefits of integrating robots in your production is its impact on productivity. Most industries lose a lot of time and resources during processes such as part transfer and pick and place tasks.

Palletizing robots are relatively fast and boast of very high accuracy degree, allowing you to complete the tasks much quickly with good accuracy.

It’s particularly suitable for repetitive tasks since the bots never get bored, and hardly need to rest from working too hard.

Automating also comes in handy during the peak seasons when you need to produce more products than usual. Thanks to their speed and no-stop operation, you’ll be able to meet your demand in the market.

-

Improve your Flexibility

Just like your competitors, your production system should be flexible enough to adapt to the changing market demands. While your workers can adopt new policies faster, a palletizing robot gives you a better edge.

Modern collaborative robots are easy to reprogram for new processes, and can thus complete a variety of tasks quickly. Another appeal to robots is the fact that it can be deployed to any environment.

You can use them in high-temperature tasks, handling radiative or corrosive chemicals, or even working with sharp tools. This saves your workers from workplace injuries.

-

Eliminate Costly Mistakes

Most errors in production occur during repetitive tasks when workers get bored and distracted. During this state, their productivity and precision is low and so they mess up.

Getting a robot can help address this situation. Since they don’t get tired, fatigued or bored of the tasks, they retain their high accuracy and produce high quality products 24/7.

With well-maintained material handling robots, you’ll increase your production speeds without having to compromise on your quality. Most importantly, you won’t have to worry about those costly mistakes that happen during packaging or transfers.

-

Reduced Production Costs

Reducing production costs is every manufacturer’s fantasy, and palletizing robots make it happen. The robots reduce your industry’s labor demands, improve your production hence allow you to sell more products and also reduce the number of products lost during production.

Maintenance costs of modern palletizing robots is cheaper than that of traditional robots. Its deployment is faster, too, meaning you get to improve your production as fast as you want.

Palletizing robots also have a quick ROI and their cost of robots is plummeting by the day. So, you don’t have to break the bank to invest in one, and you’ll get your payback in months!

You’ll, however, have to spend some time and money on training your employees on how to use it.

-

Save more Space

Robots will also save you more space on the production floor as they don’t occupy big spaces. In fact, some palletizing robots are tabletop robots, and thus you don’t force you to recreate more space for expansion.

Additionally, most palletizing robots are portable and don’t really need fixed spaces for production. You, therefore, won’t have to make significant changes to your floor plan, but some things will still have to move.

Final Thoughts

Incorporating palletizing robots into your material handling is a great way to streamline production in your industry. It adds more value to your product quality and enhances your growth potential. With that in mind, take your time when automating your material handling processes.

Look for a good palletizing robot and start enjoying the fruits of automation.